E6010

Both E6010 and E6011 are fast-freezing rods. It means these rods cool faster than other types, keeping the puddle from blowing out and getting too hot. You will be able to lay down a thinner bead that penetrates farther into your work piece.

You don’t have to clean your material up before welding, because it allows you to burn through rust, oil, paint and dirt. E6010 rods can only be used on DCEP(Direct Current Electrode Positive)

E6011

Just imagine, if electrodes are born, E6011 will be the twin sister of E6010. They are both fast-freezing rods, making them great choice for root pass and pipe welding. Their smaller welding pool leaves little slag for easy clean up. Though E6011 is designed for AC welders, it can also be used on DC welders, and this is an advantage over E6010.

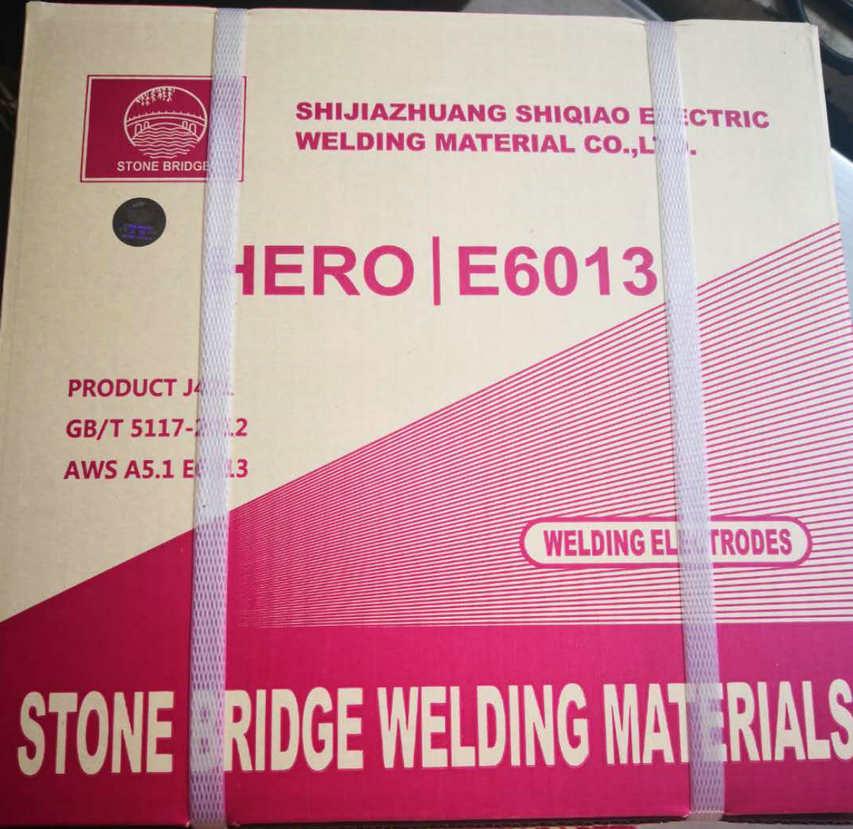

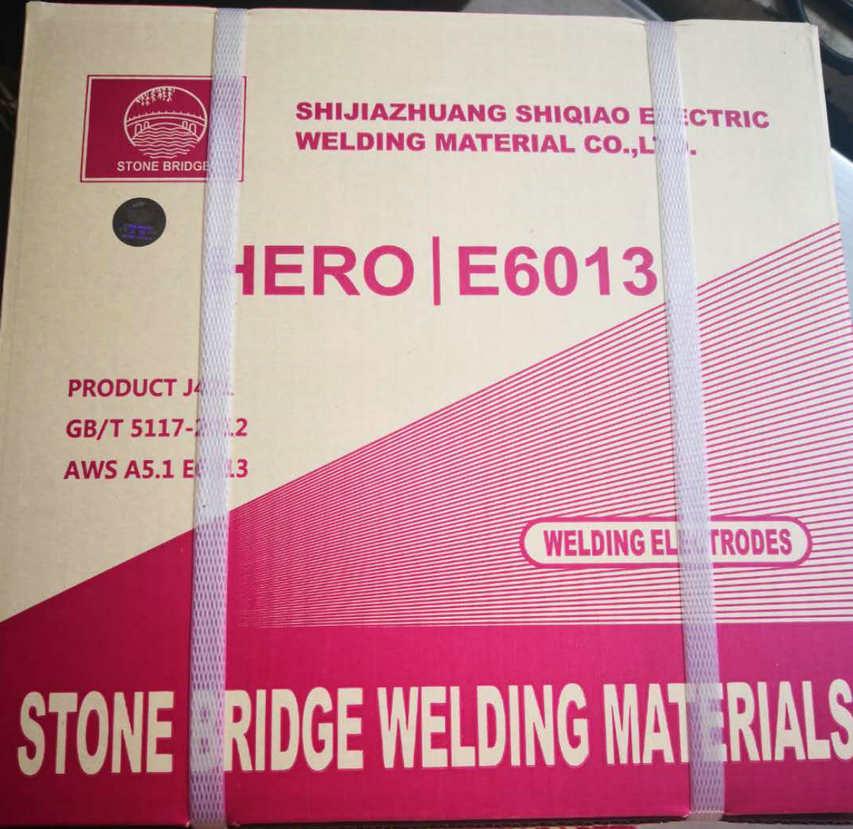

E6013

E6013 electrodes produce a soft arc with minimal spatter, offer moderate penetration and have an easily removable slag. These electrodes should only be used to weld clean, new sheet metals. E6013 is considered to be a farmer general purpose rod that is easy to use.

E7018

E7018 is a preferred choice for structural welders due to its smooth arc. Like E6013, it has mild penetration, which means you must clean surfaces of materials before welding. Likewise, E7018 has different parameters than other rods so make sure to check your settings before welding.