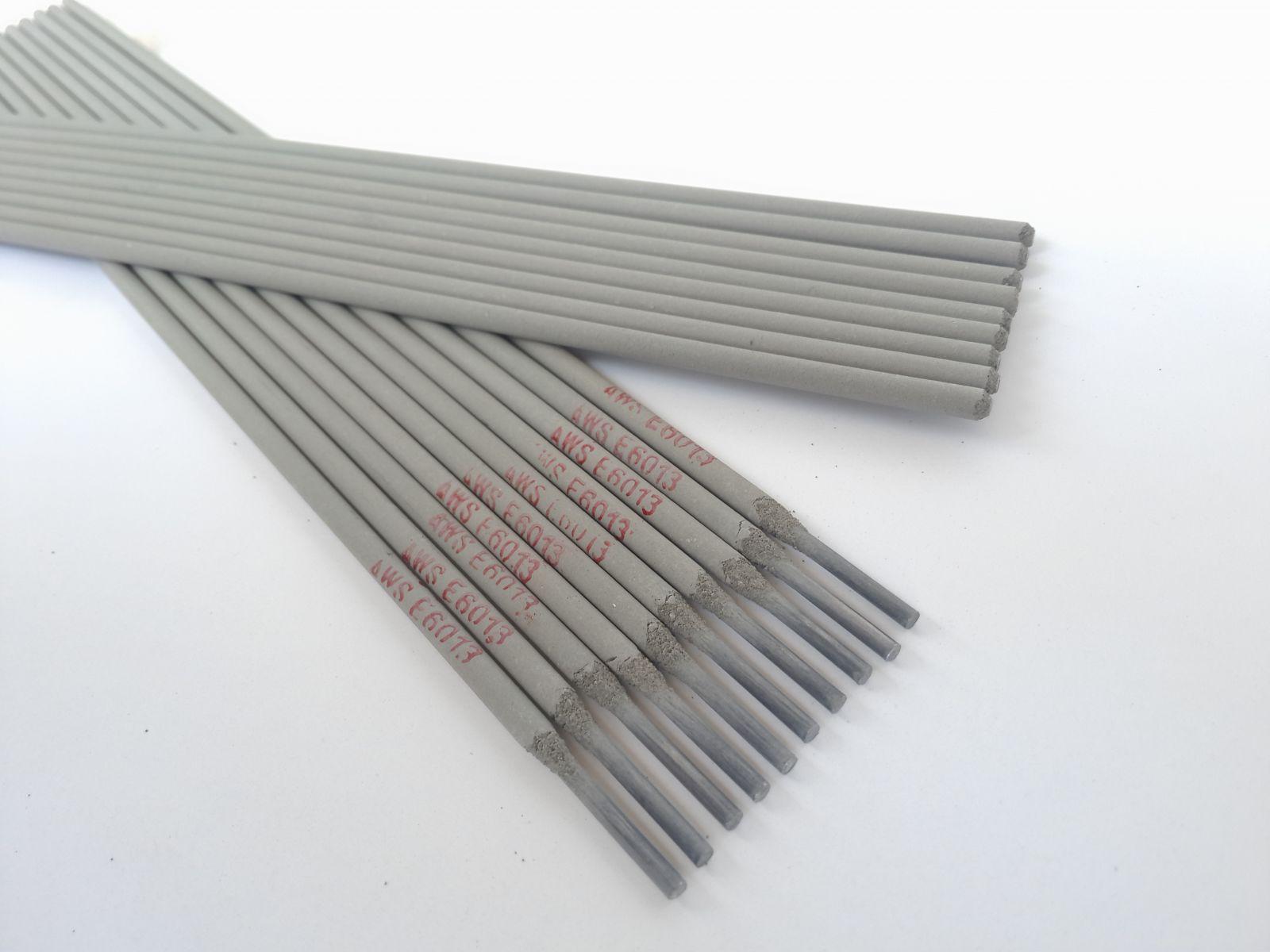

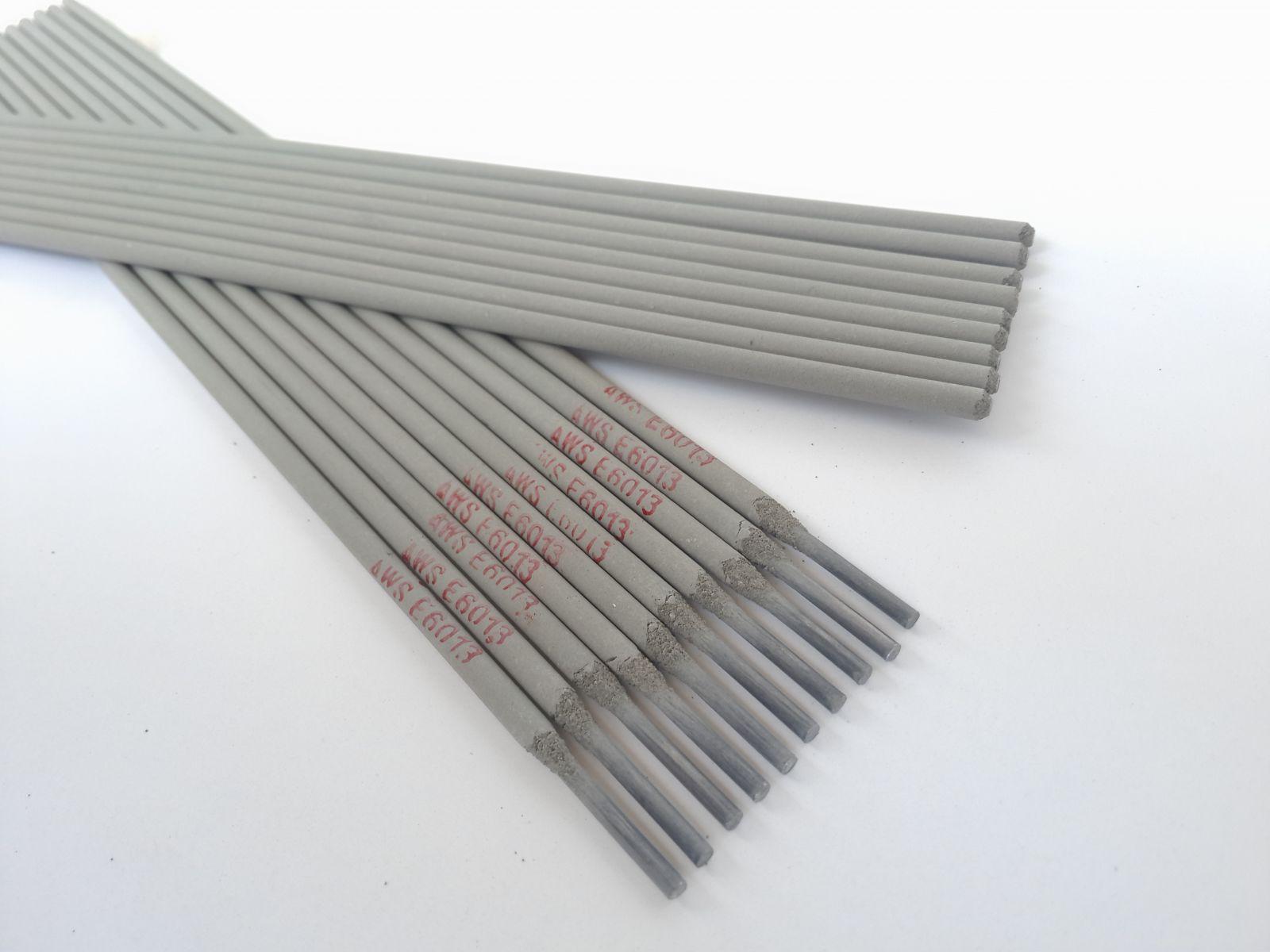

The E6013 welding rod

Once again, the 6013 is an all-position welding rod, but this time you can see that the welds will be able to withstand 60,000 pounds of stress per square inch. Not as much as the 7018, but it’s still pretty formidable and more than enough for most projects. Here, the last two digits – ’13’ – tell us that there is a high titania potassium coating on the electrode, so is compatible with AC, DC+ and DC- currents. This offers huge versatility as you can use it at low voltages and with virtually any welding machine, even those which are AC only. This level of versatility sets the 6013 welding rod apart from all the others which we’re covering today.

Beginners will probably be introduced to several other welding rods first – including the 6010 – but this is an electrode which is often overlooked as it’s just as easy to use. One main difference is that it’s typically paired with small, entry-level welding machines, whereas some of the other welding rods are usually used with slightly more advanced machines.